e

Car restoration

The restoration workshop Autoclassika specializes in high-quality restoration of retro cars, using a full technological cycle according to factory technology. In the restoration process, we use only quality materials and equipment for restoration work to ensure the highest quality results. Our specialists have extensive experience and qualifications in the field of authentic restoration of retro cars, they regularly attend exhibitions and museums, and also improve their qualifications on working trips, providing restoration services to foreign collectors.

You can see our works here

The initial condition of the retro car determines the amount of restoration work required for its restoration. The worse the initial condition of the car, the more complex and expensive the restoration will be. For cars in good initial condition, as they say, "not touched by a reckless hand" will require less work and will be cheaper. For such retro cars, it is sometimes enough to replace rubber-technical products, update the salon (replace seat fillers and clean the fabric), as well as diagnose and repair the mechanical part. Very well-preserved cars can also be subjected to conservation instead of restoration.

The company "Autoclassika" offers its customers three levels of car restoration:

Economy Level - this is demonstration quality, which is suitable for the operation of a retro car in everyday life. The use of non-original parts and interior elements is allowed, as well as the use of budget materials.

Exhibition Level - quality of work with adjustments for time and expenses. Restoration of chrome parts in Ukrainian factories, capital repair of power units, and the use of authentic interior and exterior elements.

Museum Level - this is a full restoration of a retro car using only original parts and authentic materials. Three-layer chrome plating of original parts.

Car restoration always requires full disassembly. In some cars, the body is removed from the frame. The engine, front and rear axles are disassembled and restored. If a part cannot be restored, we acquire old stock parts or manufacture a new one according to factory drawings.

We restore only original parts and use authentic materials to restore the car to its original condition.

The entire process proceeds as follows:

Firstly, the car is inspected by our specialists and a preliminary inspection act is provided, in which a conclusion is made about the originality of the car and a level of restoration is proposed.

After that, a contract and restoration protocol is signed, which indicates the stages and deadlines. Then the car is delivered to our workshop where the restoration work will be carried out step by step.

Step 1: Retro car dissembly, cataloging of parts, removal of old paint, cleaning of the body

During the car dissembly we check the available equipment with the literature on this model (drawings, parts catalogs, repair manuals, etc.). After that, the original parts list is drawn up requiring replacement or missing parts that need to be completed.

After dismantling we carry out thorough cleaning of body and parts.

The process of cleaning and removing of old paint and rust on the car depends on the goals, preservation of metal and hardness of reaching the places, it can be mechanical, chemical or manual. Respectively we may use different abrasives.

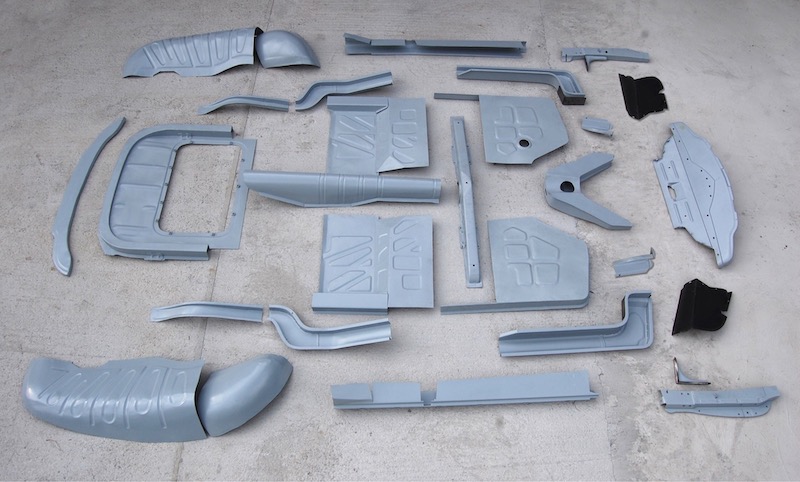

Step 2: Repair (manufacturing) of body elements

Extensive experience of our specialists allows to take into account all the nuances of tin restoration work.

If the damage of the original part is small, it is possible to conduct local repair with a special gentle technology which is important, taking into account the age of metal.

If the detail is absent or can not be restored, it is made anew by the original drawings.

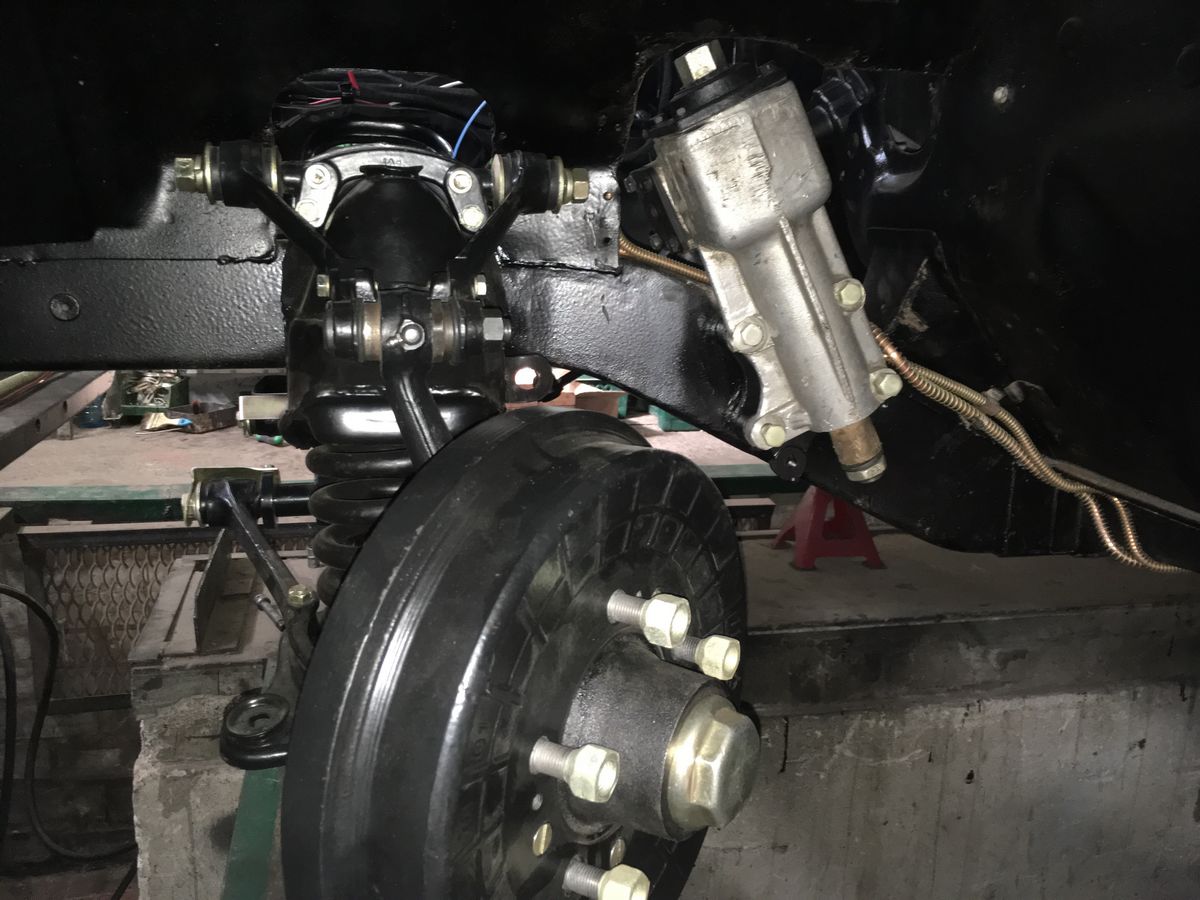

Step 3: The restoration of the car chassis

This is one of the most important steps since frame is the basis for fixing the bodywork and components of the vehicle. The future security of the recovered vehicle directly depends on the quality of the restoration work. The frame structure is common among old-timers, it is associated with the peculiarities of the design development at the time.

Damage assessment of frame deserves a special attention. Usually, after sandblasting all defects are detected, including not seen during the primary vehicle examination, such as cracks and micro-cracks, as well as the deformation defects: torsional distortion of the geometry, the longitudinal and transverse curves etc. The geometrical dimensions of the frame are reconciled with their original drawings, according to which this particular car was created at the time.

In the process of work we consider the metal fatigue, the preservation of the original design, and modern safety standards.

After the reconstitution of the "skeleton" of the vehicle, i. e. its frame, we come to the restoration of the rest of the chassis components and assemblies, such as suspension, transmission, axles, steering components, and engine.

The work on the braking system, steering, cooling system, shock absorbers, suspension, and a fuel tank begins right after we take over the vehicle. Very often this work seems to be imperceptible. But the overall picture consists of little details. At least one third of the 3 thousand hours of work needed to restore the car, is spent on these components and assemblies.

An important part of the car restoration is the repair and adjustment of the carburetor. Indicators, resource and efficient work of the engine greatly depend on how accurately this work was carried out, as well as the overall perception of the quality of the restoration work.

As for the tires, depending on the terms of reference, we offer various options for an authentic rubber mounting or we complete the car with modern tires with original tread pattern.

Step 4. Major repairs of the engine and gearbox

This is a very responsible stage. Our specialists or subcontractors perform a complete engine and transmission repair according to the technical specification, carefully selecting the necessary parts for repair.

We pay special attention to the repair and adjustment of the carburetor. During the operation of the carburetor, when overheated, physical deformation of the elements of its upper and middle parts (especially in places of their threaded and bolted connections) occurs. As a result, mechanical moving parts begin to interfere and the operation of the carburetor becomes unstable. To eliminate all existing mechanical defects, a comprehensive restoration technology has been developed based on practical experience.

The list of works for the full technological process of restoring the carburetor includes the following types of work:

- Technical diagnosis of all mechanical defects and damage to the carburetor.

- Complete disassembly.

- Replacement of worn gaskets, gaskets and fastening elements.

- Grinding and adjusting the gaps and unevenness on the horizontal surfaces of the upper, middle and lower parts of the carburetor body.

- Treatment of all parts with solvent from tar, soot and oily deposits.

- Thermal treatment of all parts at a temperature of 120-140 degrees to burn off fat residues.

- Cleaning and blowing out all internal passages and openings of the carburetor.

- Sandblasting all parts and nodes of the carburetor with soda.

- Flushing and cleaning of fuel and air gaskets, air flaps, as well as supply valves and float chambers in a 10% solution of gasoline.

- Assembly and installation of all parts and components of the carburetor.

- Adjustment and synchronization of the carburetor to ensure proper functioning and optimal fuel efficiency.

- Testing and final inspection of the carburetor to ensure that it meets the manufacturer's specifications and standards.

- Packaging and delivery of the restored carburetor to the customer.

Note: The above is a general outline of the work involved in restoring a carburetor. The specific steps and procedures may vary depending on the make and model of the carburetor, and the technician's skill and experience.

Step 5. Electroplating works in restoring the car parts

Chroming is one of the most important and labor-intensive processes in the restoration of a retro car. In line with the fashion of past years, a classic car has many chromed parts that are prone to corrosion and over time lose their external shine. In order for new chrome, for example on bumpers, to be durable, the surface of the part must be prepared: by mechanical or galvanic means remove the old coating, remove corrosion spots, repair craters, cracks, sand and polish the surface after each coating. In authentic restoration, only classic three-layer chroming (copper, nickel, chrome) with Swiss gloss-enhancing additives is used. This method allows to achieve the highest degree of shine and durability. All stages of work in preparing for galvanizing are done entirely by hand.

Step 6. Painting

We perform car painting with the application of the current technology to achieve the best results during the car restoration. Well renovated oldtimer is perceptible and attractive to the eyes, you can admire its external forms for hours. Needless to say what a significant role properly and accurately carried out painting work is playing at the perception. Therefore, the car body painting is a very serious work that requires special equipment and a high level of experts’ qualifications.

Step 7. Restoration of the car interior

Repair and complete renovation of the internal parts of the interior of retro vehicles: cushions and seat backs, side panels, door cards, floor coverings, and leather items. The works can be carried out in the full accordance with the original or other customer’s requirements. Our company uses the services of only the proven experts of the sewing salons.

Step 8: Manufacture and repair of electrical wiring

During the manufacturing of wiring harness for the oldtimer a wire wrapping is used that in color and pattern most closely matches the factory requirements for that model. The wiring is produced at a specialized facility using technology from the 1960s, but using modern high-quality materials.

Step 9. Car grade with missing parts

Autoclassic company has extensive channels for the supply of necessary spare parts, as well as a large reserve of original parts. In addition, we closely collaborate with many clubs, museums and shops that assist in searching for missing parts - whether it be a small emblem, car hubcap, radiator or entire engine.

Step 10. Vehicle assembly and testing

This is a particularly meticulous stage for true perfectionists. Each part is important, because thanks to this, the car will withstand even the most strict criticism and will have the maximum collectible value. After assembly, we conduct tests and eliminate all problems and malfunctions found. Then the car is washed, polished and returned to the customer. If necessary, we can provide further maintenance of your restored vintage car.

Remember:

- Car Restoration is always more expensive than you think.

- Restoration works last longer than you expect.

- Improper retro car restoration can negate all costs.

- Car reconstruction is justified only when you are sure that it is the dream of all your life.

However, many people who made the right choices multiply investment in 5-10 years and classic cars become more expensive over time. They are not vulnerable to the crises, ups and downs of the national currency rate, the fall of stock markets or stock quotes. Over the years they become more and more expensive. The pleasure of owning a dream can not be estimated with any wealth in the world.